MANUFACTURING :

Material Used:

Mild Steel - (Combustion Chamber

Outer, Flame tube ,Flanges, Spark Plug Fittings, Air inlet manifold, Nozzle)

ØMild

steel is the most common form of steel as its price is relatively low while it

provides material properties that are acceptable for many applications.

ØMild

steel has a low carbon content (up to 0.3%) and is therefore neither extremely

brittle nor ductile.

Brass - ( Fuel Injector & Fittings)

Alloy Type: Binary

Content: Copper & Zinc

Density: 8.3-8.7 g/cm3

Melting Point: 900-940 °C

COMPOSITION

Of Mild Steel:

Element Weight %

C 0.18-0.23

Mn 0.30-0.60

P 0.04 (max)

S 0.05

(max)

Properties

Of Mild Steel:

Density: 7,861.093 kg/m³(0.284 lb/in³)

Tensile strength: 500 MPa

(72,500 psi) Max

Young's modulus: 210 GPa.

Melting

point: 1350-1530°C (2462-2786°F)

Methodology:

• Mild Steel pipes of Required Diameter

were obtained and cut to required specifications.

• The joints were TIG welded .

• The Flanges of the sections are held by

Fasteners.

• The fittings for the fuel inlet and

spark plug holder were fabricated using manual lathe using the turning process.

• The combustion Chamber is sealed usng a

rubber O-Ring.

• The flame tube holes were drilled using

a drilling machine.

• The air flow pipe coupler was drilled

and then threaded for fitting the pressure transducer.

IN PICTURES:

FABRICATION:

Combustion

Chamber & Flame Tube:

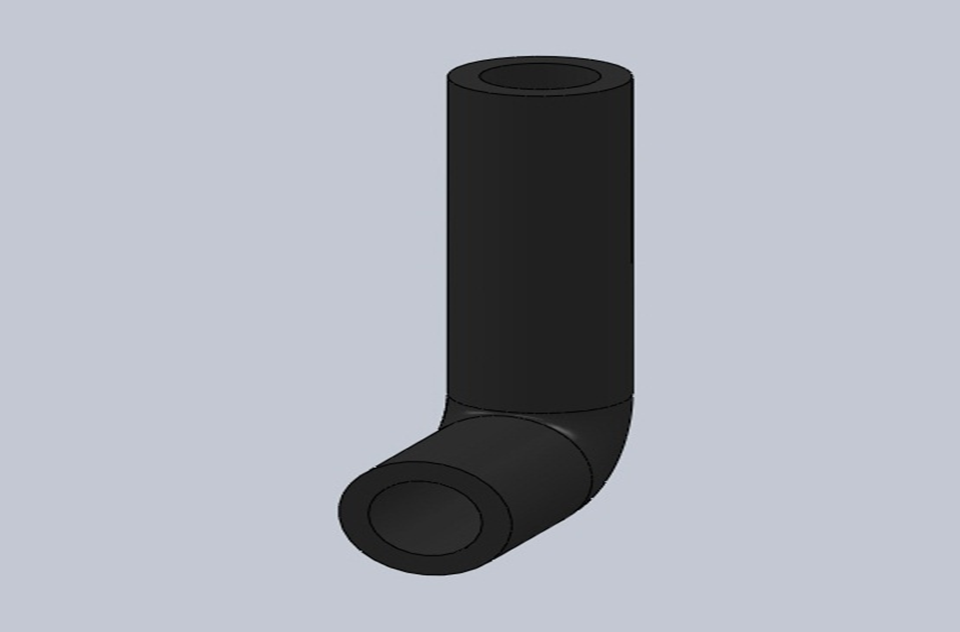

NOZZLE

FABRICATION:

As

shown in the picture the nozzle was fabricated and then TIG welded onto the

turbo's outlet . However during the the first attempt the weld didn't hold and

cracked on cooling . The weld didn't crack during the second attempt .