PROJECT 1: VALVELESS PULSE-JET ENGINE

A Valveless pulse jet (or pulsejet) is one of the simplest jet

propulsion devices ever designed, and is the simplest form of jet engine

that does not require forward motion to run continuously. Valveless pulsejets are low in cost, light

weight, powerful and easy to operate. They have all the advantages (and most of

the adisadvantages) of conventional valved pulse jets, but without the

troublesome reed valves that need frequent replacement - a valveless pulsejet can operate for its

entire useful life with practically zero maintenance. They have been used to

power model aircraft, experimental go-karts and even some

unmanned military aircraft such as cruise missiles and target drones.

HISTORY:

|

| GERMAN V1 BOMB |

The pulsejet

engine was first invented in the early 1900 by a Swedish inventor Martin Wiberg

Paul Schmidt, who engineered the first production pulsejet during the Second World War with his flying bomb, the Argus V1.

Nicknamed the “buzz” bomb because of the low hum it emitted

during flight.

Used by the Germans to bomb London from 1944-1945.

Over 9,000 V-1 were fired on England during WW2.

The pulsejet took a backseat in the engineering world when the turbofan jet

engine was invented

Has returned to the engineering scene as of late because of the interest in

Pulse Detonation Engines (PDE).

The "valveless" pulsejet is not really valveless — it just uses the mass of air

in the intake tube as its valve, in place of a mechanical valve. It cannot do

this without moving the intake air outward, and this volume of air itself has

significant mass, just as the air in the tailpipe does — therefore, it is not

blown away instantly by the deflagration but is accelerated over a significant

fraction of the cycle time. In all known successful valveless pulsejet designs, the intake air

mass is a small fraction of the tailpipe air mass (due to the smaller

dimensions of the intake duct). This means that the intake air mass will be

cleared out of contact with the body of the engine faster than the tailpipe

mass will. The carefully designed imbalance of these two air masses is

important for the proper timing of all parts of the cycle.

VALVED AND VALVELESS PULSEJETS:

•Valved:

Pedal or spring

valve construction

Harder to build

•Valve-less:

No moving parts

Easier to build

Cheaper

DESIGN:

This engine was built in

January 2012. Back then I had no idea that I will be creating jetprojects blog So

I didn't click pictures during fabrication of the engine.However the CAD

models and testing pictures and videos are available .I believe that the

following information will be useful to all DIY jet engine enthusiasts.

The

main objective of the design was to make the engine as simple as possible. So I

limited myself to simple cylindrical structures . Initially a rough hand

sketch of a simple design was made on an A4 sheet. Later a 3D model was

generated using Solid Works .

|

| COMBUSTION CHAMBER |

|

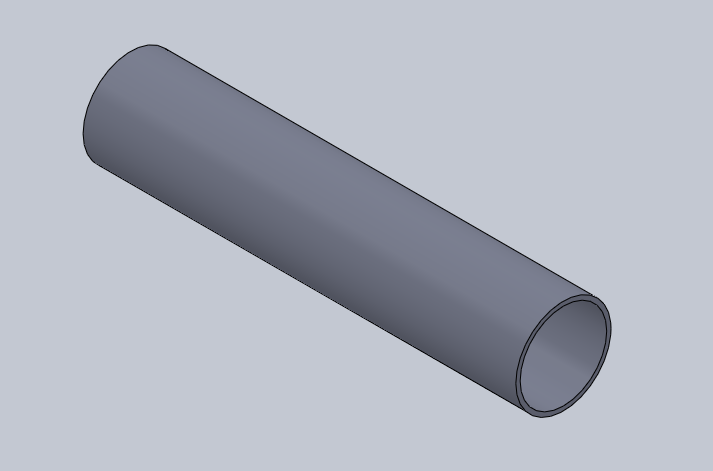

| INLET |

|

| EXHAUST |

| |||||||||

| COMPLETE ENGINE |

FABRICATION:

•

The

entire engine was made from SS304(stainless steel) Sheets and

SS304 pipe.

•

The

inlet and combustion chamber were rolled from SS304 sheet.

•

The

exhaust is an SS304 pipe.

•

The

three parts were welded together by MIG welding at a welding

Work Shop.

•

The

rolling process and welding process were done in the

Workshop.

•

The

fuel injector was made by bending and welding copper tubes.

•

LPG was used a fuel for running the engine

.

•

A 15kg LPG cylinder was used.

•

An LPG gas tube was used to link the

cylinder outlet to the

fuel injector.

•

A

high flow rate LPG regulator was also used to provide high

fuel

flow into the engine’s combustion chamber

|

| LPG (PROPANE CYLINDER) |

|

RUBBER TUBE

|

|

| HIGH FLOW RATE REGULATOR |

FUEL INJECTOR:

To explore more about Pulse Jet Valve EngineClick here

ReplyDelete